ITR repair parts coverage is considered the most extensive and complete range of repair items available in market. Throughout the last 40 years , the ITR repair parts coverage has grown and expanded through customer demand, constant market analysis and strategic acquisitions.

ITR is well known for providing the most extensive coverage of repair parts in the industry. The product range includes hydraulic parts, filtration components, transmission, frame & final drive parts and engine parts.

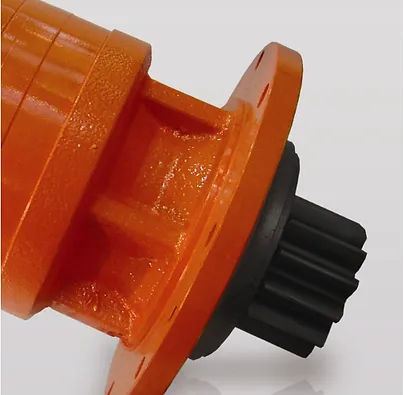

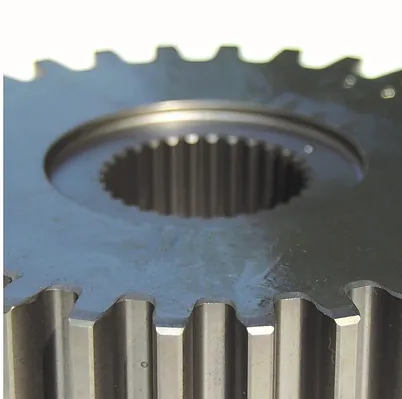

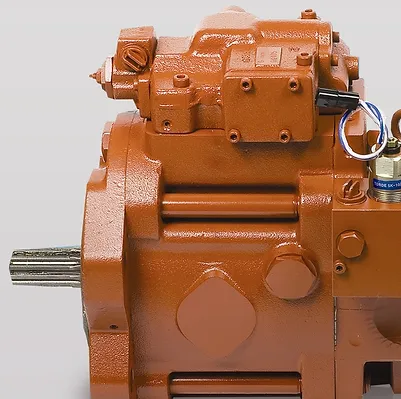

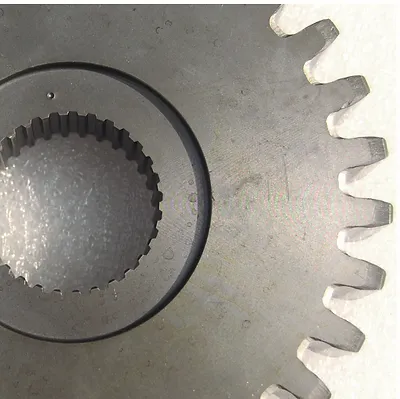

Pump Parts

ITR has an extensive range of hydraulic parts in the industry. The product range includes

These parts are suitable for a wide range of Hydraulic Main Pumps, Swing motors and Travel motors.

Breaker Tools

ITR is one of the leading suppliers of breaker tools. With its advanced technology, thorough knowledge & experience ITR has grown up in the hydraulic breaker industry.

ITR breaker tools are made with high quality steel & heat treatment processes which provide great wear resistance and exceptional breaking power.

Strict quality control is maintained on ITR tools manufacturing processes to achieve an optimum between hardness and tensile properties which reduces the possibility of breakage. Thus we ensure our customers with higher service life, quality pricing and prompt delivery.

Pin and Brush

ITR range of pins and bushing for excavators & loaders. ITR pins and bushes are characterized by improved strength, shock resistance and reduced wear and tear.

ITR can provide dotted, electroplated in addition to normal bushing. Also available are chrome finish pins. Material used for bushes is 40 Cr steel and for pins is 45# steel.

Filters

Air filter – It prevents contamination of intake air which mixes with fuel before combustion.

Oil filter – Provides clean lubricant oil thus reducing premature wear and tear in all frictional parts(piston, cylinder) thus giving maximum fuel economy.

Fuel filter – Keeps fuel clean which will prolong injector life and maintain higher fuel efficiency.

Transmission filter – It ensures that transmission fluidis clean and the transmission boxes clog free for better performance.

Coolant filter – Keeps coolant system clean.

Also available are air/oil separator & fuel/water separator.

Slew Ring

ITR is a leading supplier with specialization in design,development & manufacturing of slew rings.

ITR manufacturing facility have advanced CNC manufacturing, CNC Quenching & Testing equipment which are required for delivering slew rings with the best quality standard & highest precision.

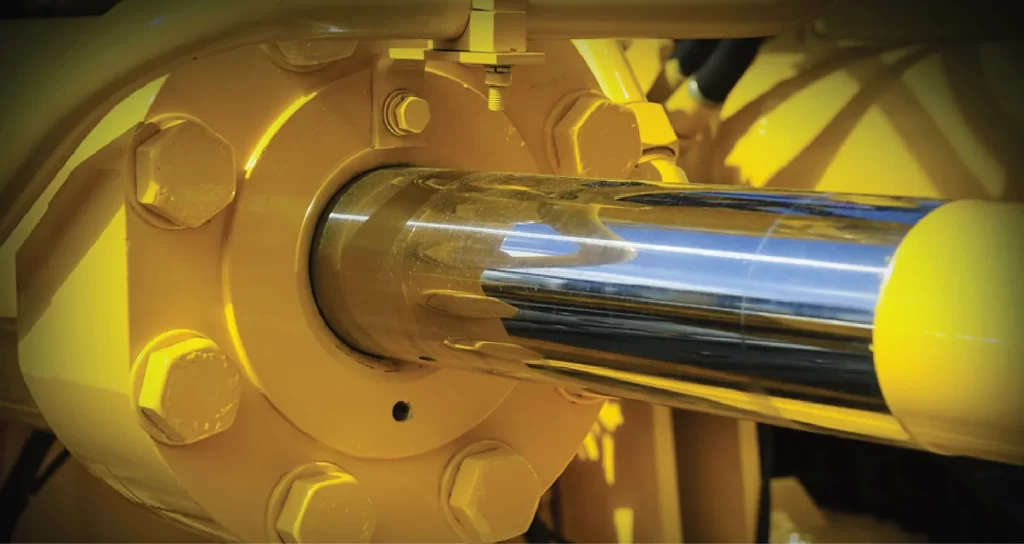

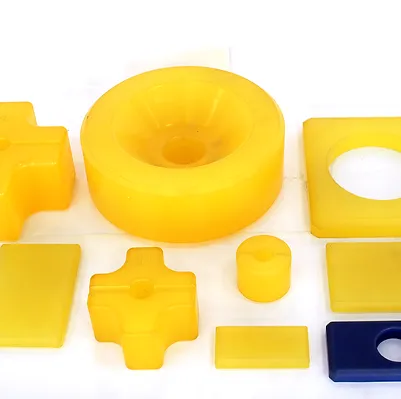

Seal Kits

Hydraulic Seals are made of Teflon and rubber and are used in construction equipment. They are developed for Used Hydraulic Cylinder market.

The seal kits include Rod seals, Buffer rings & Dust seals which perform the most important function of preventing dust contamination & any leakage in the hydraulic circuits of Construction equipment.

ITR seal kits use upgraded raw material which provides enhanced heat resistance and tensile strength. Ideal groove design helps in achieving smooth oil flow and excellent performance at intense environments.

Cylinder Repair Kit range includes Boom Cylinder Seal Kit, Arm Cylinder Seal Kit, Bucket Cylinder Seal Kit , Blade Set Kit, Center Joint Seal Kit.

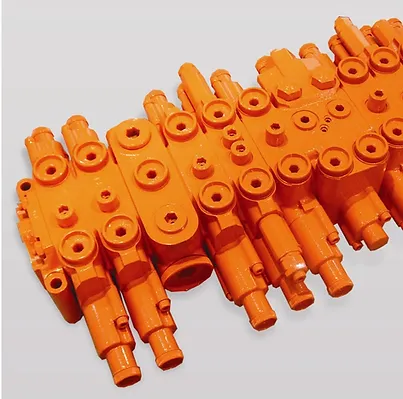

Breaker Parts

With its continuous advancement in breaker parts technology accumulation now ITR breaker parts have gained customer confidence.

The parts production facility includes advanced heat treatment, processing and measuring equipment’s which provides products that are highly reliable & durable.

ITR has in range the complete range of breaker parts like Cylinder, Piston, Front head, Chisel & stop pins, Through bolts, Front covers & bushes and Seal kits & Diaphragms for all the popular Hydraulic breaker models.

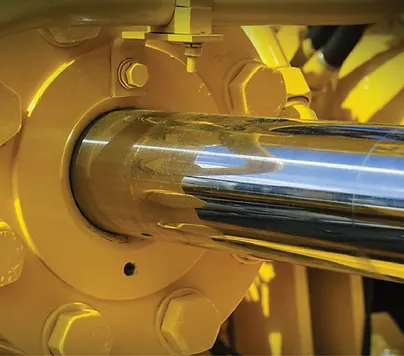

Cylinders

ITR hydraulic cylinders are truly world class and manufactured using advanced production techniques. ITR cylinders are available for a wide variety of excavator, loader, and dozer machine models.

Our full range of excavator cylinders suit up to 100 tons class machines.

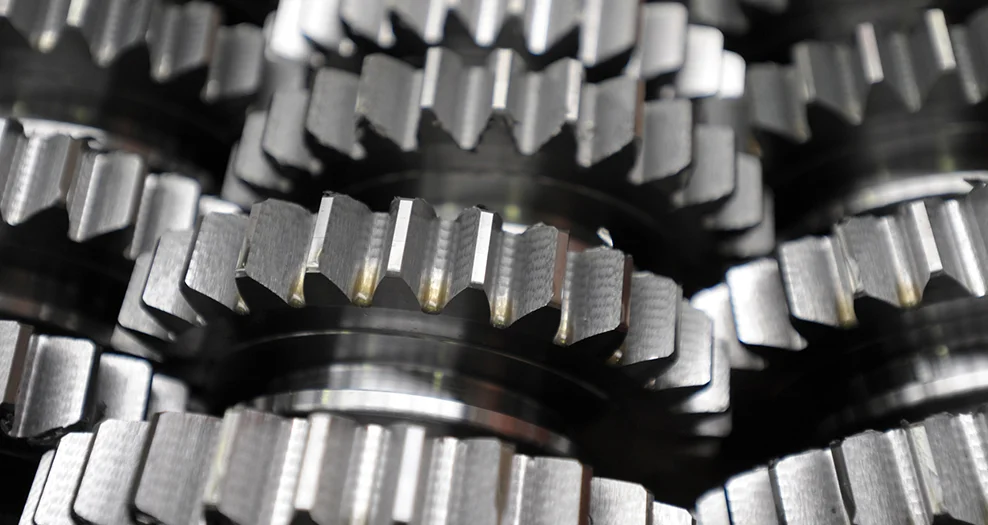

Universal Joints

ITR universal joints are made of special Chrome Molybdenum Alloy steel. Journal cross, Bearing caps are forged and heat treated which gives high strength and high load bearing capacity.

The seals made of special rubber provide greater grease retention & prevent dust intake even at high working temperatures. Needle bearings used are Heavy duty. Thus ITR universal joints provide better fitting at the best required specifications

Fuel Tanks

The issues related to the safe storage and transportation of different kinds of fuels and liquids had made ITR to develop a range of storage solutions. With the support of the factory in Italy , ITR could bring out a wide choice of fuel tanks to meet the needs and requirements of its customers.

ITR fuel tanks and relative portable fuel filling groups are entirely developed and manufactured in Italy. The wide range includes transportable tanks in polyethylene from 55 L to 980 L for transporting diesel, petrol, oil, and Ad Blue. ITR fuel tanks are distinguished by their compactness, toughness, and lightness, characteristics that make them easy to use and transport.